WGT type connecting middle sleeve drum-shaped gear coupling:

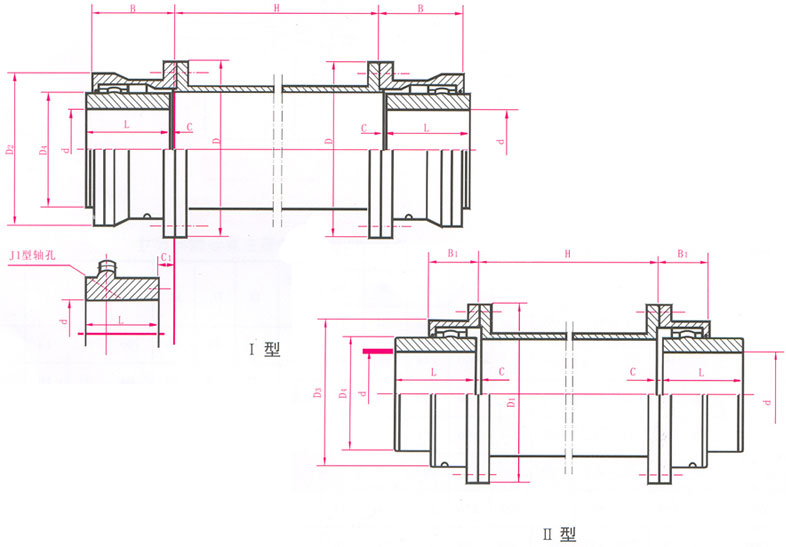

Drum gear couplingIt belongs to a rigid-flexible coupling. The gear coupling is composed of an internal gear ring with the same number of teeth and a flange half coupling with external teeth.The external teeth are divided into two types: straight teeth and drum teeth. The so-called drum teeth means that the external teeth are made into a spherical surface. The center of the spherical surface is on the gear axis. The tooth side clearance is larger than that of ordinary gears. Allows larger angular displacement (compared to the straight tooth coupling), the contact condition of the tooth can be improved, the ability of transmitting torque is improved, and the service life is prolonged.The contact state along the tooth width when there is angular displacement.It has the ability to compensate for axis deviations in radial, axial and angular directions, and has the advantages of compact structure, small turning radius, large carrying capacity, low transmission, low noise, and long maintenance cycle. It is especially suitable for low-speed and heavy-duty conditions, such as metallurgy, It is also suitable for shafting transmission of various machinery such as petroleum, chemical industry, general machinery, etc. in mining, lifting and transportation industries.

When the intermediate sleeve drum gear coupling is working, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth periodically slide relative to each other in the axial direction, which will inevitably cause tooth surface wear and power consumption. Therefore, the gear coupling needs Work in a good and sealed state.Gear couplings have small radial dimensions and large load-bearing capacity. They are often used in shafting transmissions under low-speed and heavy-duty conditions. High-precision and dynamically balanced gear couplings can be used for high-speed transmissions, such as gas turbine shafting. transmission.Because the angular compensation of drum gear couplings is greater than that of spur gear couplings, drum gear couplings are widely used. Straight gear couplings are obsolete products and should not be used as much as possible.

The characteristics of the drum gear coupling (compared with the straight gear coupling, it has the following characteristics):

1. Strong carrying capacity.Under the same outer diameter of the inner gear sleeve and the outer diameter of the coupling, the carrying capacity of the drum gear coupling is on average 15-20% higher than that of the straight gear coupling.

2. Large angular displacement compensation.When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1o, and the allowable angular displacement of the drum gear coupling is 1o30', an increase of 50%.Under the same modulus, number of teeth, and tooth width, the allowable angular displacement of the drum gear is larger than that of the straight tooth.

3. The drum-shaped tooth surface enables the contact conditions of the inner and outer teeth to be obtained, avoiding the disadvantages of spur tooth end edge extrusion and stress concentration under the condition of angular displacement. At the same time, the friction and wear conditions of the tooth surface are reduced, and the noise is reduced. Long maintenance period.

4. The tooth end of the outer gear sleeve is in the shape of a horn, which makes the assembly and disassembly of the inner and outer teeth very convenient.

5. The transmission reaches 99.7%.

Based on the characteristics of warp, at present, drum-shaped teeth have generally been substituted for straight-tooth couplings.

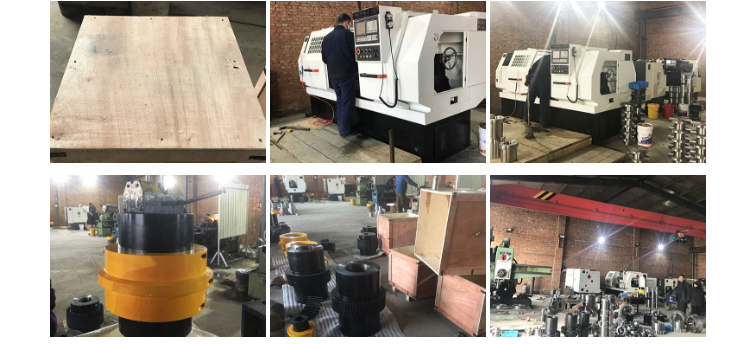

Hangzhou Hengli Transmission Co., Ltd. is an enterprise specializing in the research and production of couplings.Our company is equipped with various equipments and strong technical force. It is a manufacturer of various types of couplings for many domestic machinery industries.The main products of our company are diaphragm couplings, tire couplings, roller chain couplings, drum gear couplings, star elastic couplings, slider couplings, flange couplings , Plum-shaped elastic coupling, elastic pin coupling, elastic sleeve pin coupling, elastic pin gear coupling, etc.To meet customer needs, we also undertake surveying, mapping and manufacturing of other couplings.The company has realized CAD computer-aided design and information management, integrated research and manufacturing, has rich manufacturing experience, perfect testing methods, complete varieties and specifications, and stable and reliable quality.

In terms of the market, the company has maintained long-term customer relationships with many domestic steel plants, and the product quality and delivery time have been highly praised by customers.We have established a stable supply relationship with many domestic papermaking, petroleum and other companies, and actively explore new sales markets with the quality and advanced performance of the products. The company has a group of professional and technical personnel with rich practical experience. At the same time, we have a Batch sales and after-sales personnel provide advanced transmission technology services for cooperative units to ensure smooth and efficient operation of the equipment of cooperative enterprises.

Since the establishment of the company, its products have been sold all over the country and have been deeply favored by new and old customers. Based on the principle of good faith, it has established long-term cooperative relations with many customers. Now our company is further strengthening employee technical training and improving technology Level, inject high technology into products, and strive for better products and more affordable products.The company adheres to the corporate philosophy of benevolence, integrity, pragmatism, and innovation, and strives to provide users with high-quality products and satisfactory services with advanced production management and strict quality control.

Entreprise's news

News

Copyright © 2018-2019 Hengli Transmission All Right Reserved.